Harnessing Heat

Charting our thermal efficiency journey

Risk & Progress explores risk, human progress, and your potential. My mission is to educate, inspire, and invest in concepts that promote a better future for all. Subscriptions are free. Paid subscribers gain access to the full archive and Pathways of Progress.

We have examined how knowledge drives progress, compressing the cost of goods and services, creating new beneficial order from disorder. Through the accumulation of knowledge, we humans have forged a counterentropic world in our image, but all of this requires energy. While the Agricultural Revolution was an energy revolution for our stomachs, powering more human brains, humanity would have remained agrarian if it were not for another energy revolution: the Industrial Revolution. This revolution fed the fires of our machines, using heat energy to do work. Here, we chart the progress of engine technology, how heat machines changed our world, and what this may imply about the future of energy.

External Combustion

The basic heat engine, the idea that water, heated into steam, could be used to make things move, we a pre-industrial discovery. Thousands of years ago, inventors had built devices that did just that, but these simple machines were little more than amusement pieces and curiosities. They were inventions only, novel ideas with incredible unrealized potential. It took the hard work and ingenuity of engineers and entrepreneurs to transform them into true innovations. And like most such innovations in the story of human progress, no single individual can lay claim to having invented them.

External combustion technology was the first to be commercialized. In external combustion, heat energy is directed into a medium (usually water) where it boils into steam to do work. The Newcomen steam engine, invented circa 1705, was massive, inefficient, and difficult to operate. It was, nonetheless, the first heat engine to achieve commercial success. The design employed a coal-fed boiler that heated water into steam. Above the boiler, a cylinder collected that steam beneath a piston. The pressure of the steam pushed up upon the piston, and at the apex, cool water was injected into the cylinder, creating a partial vacuum. This vacuum allowed the natural air pressure to push the piston back down, where the process could be repeated.

First installed commercially in 1712, the Newcomen engines were used primarily to pump water out of coal mines. They serve as a great example of how necessity breeds innovation, but also the other way around. The machines enabled coal miners to explore deeper deposits to supply Britain’s rapidly growing coal demand, while the machines themselves helped fuel that demand with their voracious appetite for the fossil fuel. Newcomen engines were only economically viable near coal mines, due in part, to their extremely poor thermal efficiency, which averaged about 0.5 percent.

It didn’t take long for engineers to address the Newcomen’s limitations. James Watt realized that most of the engine’s heat energy was wasted reheating the cylinder after it had been cooled. He addressed this by adding a separate cylindrical condenser where cool water was injected, allowing the main cylinder to remain hot at all times. He also devised new seals, better machining techniques, and other innovations that increased thermal efficiency to between 2 and 3 percent. The first Watt engine went into operation in 1776, but by 1783, Watt had gone further, developing a “double-acting” engine that admitted steam to both sides of the piston, alternating it back and forth. This double action could be used to convert a simple “up and down” motion into a more useful circular motion, replacing water wheels and windmills. Nascent factories could now operate their machines anywhere, not just near sources of running water.

These early steam engines were “atmospheric,” most of the work was done by the weight of the atmosphere pushing down on a partial vacuum created when the steam was condensed. In theory, an engine that utilized the steam, not the atmosphere, to move the piston, could be more efficient, compact, and powerful. These “strong steam” designs were resisted by engineers for decades because they were seen as unsafe. Only after ~1810 were safety concerns sufficiently addressed. The Cornish engine, for example, used high-pressure steam to push down on the piston, helped along by a vacuum underneath. The design was aided by the advancement of boiler technology, like cylindrical flued boilers, which could withstand higher pressure than the prior “haystack” boiler designs.

By 1830, single-flued boilers gave way to multitubular designs, which greatly increased the surface area in contact with water, heating the water into steam more efficiently. Additional improvements in design and materials more than tripled thermal efficiency to about 10 percent. Further, when laid horizontally, multitubular boilers could make the steam engine compact enough for mobile applications. This led to the first steam-powered ships and the practical locomotives, including the famous “Rocket.”

The last major iteration of the steam engine, the steam turbine, emerged in the closing decades of the 19th Century during the Second Industrial Revolution. Designed and promoted by Charles Algernon Parsons, the steam turbine eschewed pistons, using high-pressure steam to rotate a turbine instead. This design doubled thermal efficiency to over 20 percent. The steam turbine was put to use on ships almost immediately, enabling faster sea travel, and it also became the engine of choice for generating electricity. The steam turbines arrived just in time, in fact, to provide affordable electricity just as the first electric light bulbs began hitting the market.

Internal Combustion

While steam engines remained an important source of power through the “Second Industrial Revolution,” we had about reached the limits of their potential. The Second Industrial Revolution was not defined by coal and steam; it was instead driven by petroleum and internal combustion. Liquid petroleum had advantages. It could be refined into specialty fuels like kerosene, diesel, and gasoline, and be easily transported via pipelines. Petroleum products were also better for the environment. Compared with coal, they emit fewer pollutants and about 30 percent less carbon dioxide for a given unit of energy.

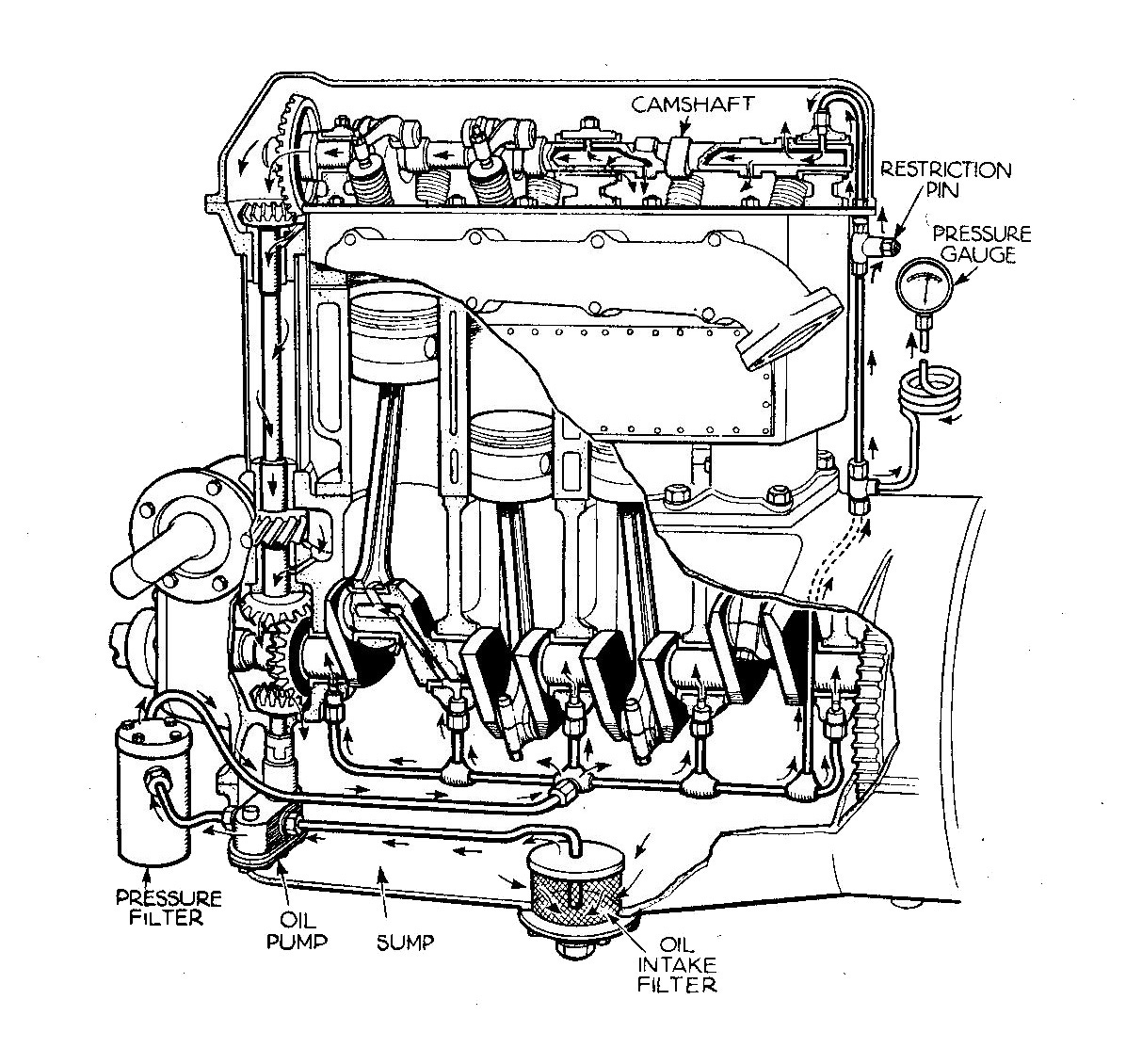

In addition, internal combustion engines could harness that energy more efficiently than external combustion engines because they removed the intermediary medium (water) and directly combusted the fuel instead. This also allowed internal combustion engines to be made smaller, lighter, more compact, and power-dense. In all ICE engines, a fuel/air mixture is introduced into a series of pistons, where the mixture is ignited to create a small explosion. The pressure of this mini-explosion is then used to draft a shaft connected to a flywheel, which converts the “up and down” movement of the pistons into a circular motion. In diesel engines, pressure alone ignites the fuel/air mixture. In gasoline engines, on the other hand, a carefully timed ignition spark is required.

The first successful four-stroke engine, known as the “Otto cycle,” began production in 1876. While initially less efficient than their steam counterparts, ICEs were more compact and better suited for mobile applications. Efficiency advances come gradually, and in the early 20th century, the gasoline ICE won in a three-way race with steam and electricity to power the automobile. Around the same time, even more efficient diesel engines became the engine of choice for trucks, ships, and trains. The single greatest achievement of internal combustion, however, was unlocking powered flight.

While unpowered gliders had been experimented with for some time, powered flight was thought, by many, to be impossible due to the limitations of engine technology. This was the primary challenge that the Wright Brothers faced when building the Flyer. They needed a powerful, compact, and lightweight engine, something that steam couldn’t provide. In fact, at the time, internal combustion engines couldn’t either. The Wrights were forced to innovate and fashion a custom engine with an aluminum block. This lightweight engine could still barely get the Flyer off the ground, but it unlocked an entirely new paradigm for travel.

In another example of how innovation can be self-reinforcing, it is notable that the Wright’s aluminum engine would have been impossible just a few years earlier. Aluminum deposits on Earth are rarely pure; extraction of the metal was historically expensive, and aluminum was worth more than gold. By the turn of the 20th Century, however, aluminum prices had fallen due to the development of the Bayer refining process in 1889. This energy-intensive process was made possible by…you guessed it…the proliferation of relatively efficient steam-powered electrical generation plants.

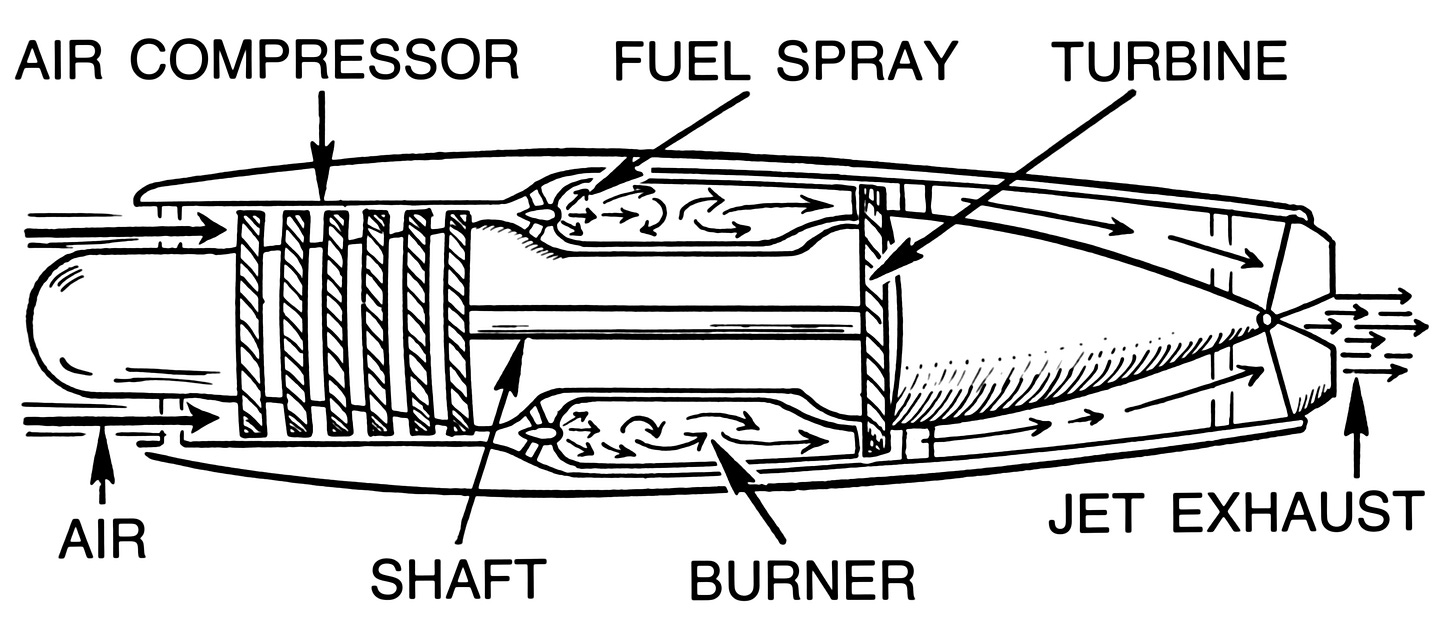

By the 1950s, internal combustion engines dominated the skies and streets of civilization. Diesel engines had more than doubled the thermal efficiency of their steam counterparts, achieving nearly 50 percent thermal efficiency. And like external combustion engines that began with pistons, internal combustion also found its way to rotating turbines. The jet engine was simultaneously and independently invented in Germany and Britain in the 1930s. Jet engines utilize a compressor that compresses incoming air, where it is then mixed with kerosene fuel and ignited in a combustion chamber. The high-pressure explosion creates exhaust thrust that is directed out the rear of the engine, providing a forward propulsive force. As it exits, some of this energy is captured by a turbine that connects to a shaft and drives the compressor.

Without pistons, jet engines created little vibration during operation, reducing engine wear and allowing them to reach higher speeds. Just as the steam turbine made sea travel faster and cheaper, the jet turbine made air travel faster, safer, and more affordable for the masses after the 1960s.

The Final Fossil Fuel?

Engine innovation did not stop there, but the incredible leaps in thermal efficiency appear to be over. In part, because we are approaching the physical limits of using heat energy to do work. In the early 21st century, a new fossil emerged front and center: natural gas. Natural gas is more environmentally friendly than petroleum, emitting fewer pollutants and about 30 percent fewer carbon emissions per unit of energy. We can also extract energy from natural gas greater efficiently using a Combined Cycle Gas Turbine (CCGT). With CCGTs, natural gas is ignited and used to drive a turbine, much like a jet engine. Instead of dumping the hot exhaust, however, it is used to heat water and transform it into steam, driving a separate turbine. CCGT devices have broken the 60 percent thermal efficiency threshold, providing low-cost, low-environmental impact energy for the 21st century.

I have charted the engines of progress above. The trend is unmistakable. Our ability to efficiently extract energy from fossil fuels has risen dramatically over time, rising from 0.5 to over 60 percent thermal efficiency. Just as the thermal efficiency of an engine design appears to peak, a new one is developed that extracts energy with still greater efficiency. At the same time, our preferred fuels have become significantly less carbon-intensive and less polluting. As we will discuss in more detail later, each step up this “energy ladder” from coal, to oil, to natural gas, saw dramatically fewer pollutants released per unit of energy. This fact has tremendous implications for the future of energy capture and suggests a future that moves us beyond fossil fuels.

Next in this series:

Previous:

The future of fuel-to-energy efficiency is bright! Thermoelectrics could help capture more energy from waste heat and things like solid oxide fuel cells or companies like Lightcell energy might squeeze more energy out of fuels.

https://en.wikipedia.org/wiki/Thermoelectric_generator

https://en.wikipedia.org/wiki/Solid_oxide_fuel_cell

https://www.lightcellenergy.com/